Clutch Housing

Aluminium Die Casting in India

Clutch Hub

Aluminium Die Casting in India

Clutch Wheel

Aluminium Die Casting in India

LED Street Light

Aluminium Die Casting in India

Street Light Fixtures

Aluminium Die Casting in India

Clutch Flange

Aluminium Die Casting in India

Injection Cover

Aluminium Die Casting in India

Bone Cutter

Aluminium Die Casting in India

Clutch Wheel

Aluminium Die Casting in India

Cap Cover

Aluminium Die Casting in India

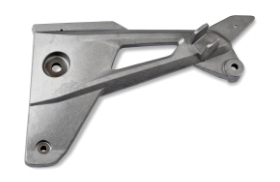

Step Holder

Aluminium Die Casting in India

Sadguru Autocomponents also cater to the needs of various OEMs for non-automotive products in aluminium, like motor bodies, cooling fans, surgical equipment, industrial LED street light fixtures, and LED floodlights. SAPL also manufactures 12-124 watts LED street light & floodlight in its own brand name. Our LED street light fixtures are designed for a better thermal efficiency, weather resistance, and are IP67 rated. We are the preferred supplier to many LED Street light OEMs for semi-finished and fully-finished LED Street Lights & Floodlights.

State of Art Die CastingFacility

High Pressure Die Casting

We have a full-fledged HPDC facility with machines ranging from 150-400 tons and a strong die maintenance process.

Machining Division

Our in-house CNC / VMC division features a fleet of machines from renowned brands for an end to end die casting solution.

Standard Room & Spectro Lab

SAPL follows the most commonly used quality core tools such as APQP, PPAP & SPC to ensure world-class quality assurance.

Surface Finish

With an in-house shot blasting facility & through our partner concerns, SAPL can provide a variety of surface finish options for your aluminium casting product needs like powder coating & anodising.

We Manufacture Aluminium Castings ThatPerform!

Infrastructure

Our shop floor features a fleet of fully automatic High Pressure Die Casting machines ranging from 150 tons to 400 tons. The machines are from renowned brands like TBC Taiwan, HMT, Colosio Italy & Toyo Japan. On the other hand, our best in class machining division is equipped with a wide range of CNC turning machines and a variety of special-purpose machinery providing drilling-tapping, broaching and shot-blasting functions.

Infrastructure

Our shop floor features a fleet of fully automatic High Pressure Die Casting machines ranging from 150 tons to 400 tons. The machines are from renowned brands like TBC Taiwan, HMT, Colosio Italy & Toyo Japan. On the other hand, our best in class machining division is equipped with a wide range of CNC turning machines and a variety of special-purpose machinery providing drilling-tapping, broaching and shot-blasting functions.

Quality Statement

Sadguru Autocomponents Pvt Ltd processes around 120MT of aluminium castings per month. We are an ISO certified company and have consistently achieved a low rejection rate of 0.06%. Our record customer end ppm stands at 620 against 5000 ppm. We also practice TPM, TQM, and 5S. With our dynamic management and technical team, we handle critical components in large volumes. A humble beginning with a single pressure die casting machine to a full-fledged Pressure Die Casting Solution in 2020, we are achieving new heights every year. Under the leadership of our Managing Director Mr Anand Mahalunkar, we have been growing steadily with a loyal customer base due to his robust customer-centric approach and policy.

Mission Statement

Sadguru Autocomponents Pvt Ltd continues to provide low-cost aluminium castings to the customer with highest quality standards and timely delivery. Our robust customer-centric approach gives us a competitive edge and has made us the most preferred supplier of aluminium castings across various industries like automotive, electrical, surgical, and architecture.

Vision Statement

Sadguru Autocomponents Pvt Ltd strives to be the best aluminium die casting manufacturer MSME in India. Our aim is to be the most technologically advanced and innovative die caster in India.