SAPL is one of the leading aluminium die casting companies in chakan

With over a decade of experience in the aluminium die casting industry, Sadguru Autocomponents has established itself as one of the leading aluminium pressure die casting companies in Chakan. We are the preferred supplier for products in the automotive industry and handle components with a zero-tolerance level.

ProductGallery

Clutch Housing

Aluminium Die Casting in Chakan

Clutch Hub

Aluminium Die Casting in Chakan

Clutch Wheel

Aluminium Die Casting in Chakan

LED Street Light

Aluminium Die Casting in Chakan

Street Light Fixtures

Aluminium Die Casting in Chakan

Clutch Flange

Aluminium Die Casting in Chakan

Injection Cover

Aluminium Die Casting in Chakan

Bone Cutter

Aluminium Die Casting in Chakan

Clutch Wheel

Aluminium Die Casting in Chakan

Cap Cover

Aluminium Die Casting in Chakan

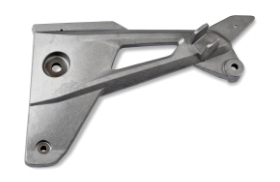

Step Holder

Aluminium Die Casting in Chakan

Industries We Serve

Automotive

Sadguru Autocomponents Pvt Ltd specializes in manufacturing a wide range of products in transmission like the clutch hub, clutch housings, clutch plates, and flange. We handle critical components in large volumes with our dynamic management and technical team. SAPL is the preferred manufacturer of aluminium castings in Chakan, the automotive industrial hub in Pune.

LED Street Light Fixtures

SAPL is the preferred supplier for LED Street Light Fixtures for various OEMs. Our LED street light fixtures are designed for better thermal efficiency, high weather resistance, and are IP65 rated. Our facility in Chakan, Pune, is well-equipped to provide a complete ready-to-assemble solution for all your LED street light product needs.

Electrical & Surgical

Sadguru Auto’s Chakan facility supplies a range of electrical & surgical aluminium pressure die casted components for the European market. Our robust infrastructure facilitates a ‘ready to assemble’ solution for the customers.

Why SAPL?

- PBest in class High Pressure Die Casting Facility in the automotive hub of Chakan, Pune

- PIn-house machining division with CNC, VMC & Special Purpose Machinery

- P10+ Years of experience in the automotive industry

- PExpertise of handling high volume of critical aluminium castings with zero tolerance level

- PExperience of working within 5 microns tolerance

FAQs

What is aluminium die casting?

Aluminium die casting is a manufacturing process where a specific grade of molten aluminium is shot into a metal die cavity at extremely high pressures. During the application of such force, the mould is closed tightly with hydraulics’ help. Post the pressurized shot the aluminium alloy solidifies, the mould opens, and the casting ejects. The aluminium pressure die casting process produces accurately defined, smooth & textured aluminium components.

Why is aluminium preferred in the die casting process?

Aluminium alloy assists in achieving lightweight parts through aluminium high pressure die casting. The aluminium castings have excellent surface finishing options compared to other metal components. Moreover, aluminium castings are corrosion-resistant and retain high dimensional stability with thinner walls. Primarily, aluminium die casting components are used in various industries due to their lightweight properties & cost-effectiveness.

Can you customize aluminium castings according to our requirement?

Yes, SAPL has successfully established itself as a pioneer in the aluminium die casting industry. With over a decade of experience and a full-fledged aluminium die casting facility in Chakan, we can manufacture precise & cost-effective aluminium castings with an optimum design for improved functionality. Once we receive a requirement enquiry, we start with understanding the customers need, functional requirement & accordingly customize the casting before the mould design stage to ensure cost, functionality & quality competitiveness.

Why choose SAPL?

Sadguru Autocomponents Pvt Ltd has been manufacturing a wide range of transmission products like the clutch hub, housings, plates, and flange for over a decade. Our high-pressure die casting facility in Chakan features state of the art HPDC shop floor with machines from premium brands like TBC, Colosio, & BMC. SAPL can handle aluminium castings with zero tolerance levels with ease. Working with us ensures you have a competitive edge over your competitors in cost, quality & delivery. Our plant in Chakan is well-equipped with CNC, VMC, & special-purpose machinery to provide you with a ready to assemble product solution. Finally, with a robust quality assurance department, we make sure to deliver excellent quality aluminium castings to ease working for our esteemed customers.

What is our high pressure die casting facility in Pune like?

Aluminium High Pressure Die Casting Shop Floor–

- TBC 150 Tons – 1 No

- BMC 200 Tons – 1 No

- TBC 250 Tons – 1 No

- Colosio 250 Tons – 1 No

- TBC 350 Tons – 1 No

- Toyo 350 Tons – 1 No

- SS Engineering 400 tons – 1 No

Machining Division & CNC Turning Centre –

- CNC Turning Centre Ace Micromatic & Jyoti – 12 Nos

- Multi-spindle Drill & Tap Machines – 10 Nos

- Broaching Machine – 2 Nos

- Bush Fit Machine – 2 Nos

- Hydro-Pneumatic Press 2 Nos

Quality Equipment –

- Spectrometer

- Hardness Tester

- Surface Finish Tester

- Air Gauge

- Special Spinning Gauge

- Relation Gauges

Others –

- Bandsaw – 1 Nos

- Shot Blasting – 1 Nos

- Sandering – 3 Nos

What is our quality policy?

Sadguru Autocomponents Pvt Ltd processes around 1500 tons of aluminium castings every year. With an ISO certified company which also practices total productive maintenance, total quality management, and 5S, you can be at peace to meet your schedules within the desired time, quality & cost. SAPL has proven to be one of the most preferred aluminium die casting companies in Pune due to its customer-centric approach.

What makes us one of the leading aluminium die casting companies in Pune?

Sadguru Autocomponents Pvt Ltd is located in the industrial hub of Chakan in Pune. Our High Pressure Die Casting plant facilitates us to manufacture aluminium components up to 1.5kg. Our strategic location, a full-fledged high pressure die casting facility, and robust quality assurance team ensures timely delivery and excellent quality. We are one of the most awarded aluminium castings manufacturers in Chakan, especially across the automotive industry. SAPL exhibits itself as an expert in manufacturing clutch hub, clutch wheel, clutch plate, and clutch housings. The automotive industry is extremely competitive and requires high precision with zero tolerance. We have successfully established ourselves as the preferred auto components die caster due to our excellent quality record.